From our own production: Each and every roller according to customers' requirements

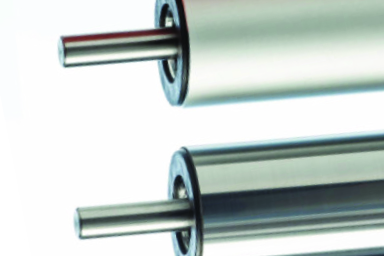

DRECKSHAGE manufacture precision aluminium idler and spreader rollers to customers’ specifications. Equipped with a vast vertical range of machinery, DRECKSHAGE always come up with the perfect solution to each and every application.

Our EconomicRoll is a sophisticated low-cost alternative to conventional aluminium rollers, providing additional technical advantages. As an option to the DRECKSHAGE EconomicRoll we specialise in standard aluminium idler rollers designed to customers’ individual specifications. Comprehensive services such as of rubber coatings, non-stick coatings or select surface finishes ensure convenient access to everything you need from one single source.

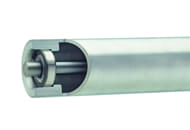

Complementing our range of idler-, guiding-, dead shaft and live shaft rollers, the DRECKSHAGE EcoStretchRoll constitutes a completely new form of spreader roller.

Our product groups

|

EconomicRoll The better solution for a broad variety of applications |

|---|---|

|

Spreader rolls for wrinkle free fabric web guidance |

|

Aluminium rollers When weight is of decisive importance |

|

Surface finishes Our wide range of services also features all sorts of different surface coatings and finishes which we will be pleased to provide. |